Team

| Anantajit Subrahmanya (as85) – ECE 110 |

Tanmay Kant (tkant2) – ECE 110 & ECE 120 |

Varun Kowdle (vkowdle2) – ECE 120 |

| David Lin (davidzl2) – ECE 110 & 120 |

Purpose

Our goal is to build a “smartboard” that has the ability to save, sync and restore writing, while preserving the tactile experience that blackboards and whiteboards provide.

Basic - Must Have Features

Ability to draw straight lines on a whiteboard, with positioning; meaning, running the same program should result in lines being drawn in the exact same location every time.

Ability to draw simple Bezier curves. Just like the straight line, these should be drawn in the same location every time on the whiteboard.

Retracting mechanism to disable/enable the pen from drawing continuously

Ability to swap out the pen without needing to completely take the device apart.

Ability to take a picture of the whiteboard.

Challenge - Target Features

- Ability to convert a picture into a series of Bezier curves (software only)

- Save and Restore functionality for the board

- Autocapping feature to prevent ink from drying out

- Phone or computer application that makes it possible for anyone to use the smart board

- Erasing tool attachment to drawing tool

- Cost of hardware: under $50

Reach - Features We Would Like To Have

- Chalk support - requires more pressure on the board

- Multicolor support - switching between multiple markers without human intervention

- Remote whiteboarding session - two people have smartboards, and can "sync" up their boards to make whiteboarding more natural

- Auto-slide generation - automatically breaking up a 1-2 hour blackboard session into a set of slides

- Whiteboard to SVG generation - converting our bezier curves into an SVG that any machine can view

- Even lower cost: $25

Background

Due to COVID-19, many professors and TAs are using iPads, Microsoft Onenote, Powerpoint presentations, etc instead of the traditional blackboards and whiteboards in classrooms. This makes it easier for people to see the content of the whiteboard, but this has two main issues.

First, writing on a blackboard or a whiteboard FEELS better. Hand cramping is much less of an issue, and the resistance that a marker or a piece of chalk give is much nicer than swiping on a glossy screen. The tactile experience is simply more enjoyable while looking at a screen can cause red eyes and headaches.

The second reason for this is that it makes it easier for multiple people to collaborate on a single whiteboard. Our goal is to get the price of components for these smartboards that every student can have a mini version of the smartboard in their study area. This should hopefully be possible by using smartphones for much of the heavy computing. Sending work would then become as easy as sharing the state of one person’s board with another person, which takes the pains of reading scanned work out of the picture.

In a nutshell, our "tactile smartboard" is an extension of what is known as a "pen plotter." We are taking a normal pen plotter, and using software to make it easier for people to transfer and save drawings that are either drawn by a machine or drawn by a human (these are not basic features, though).

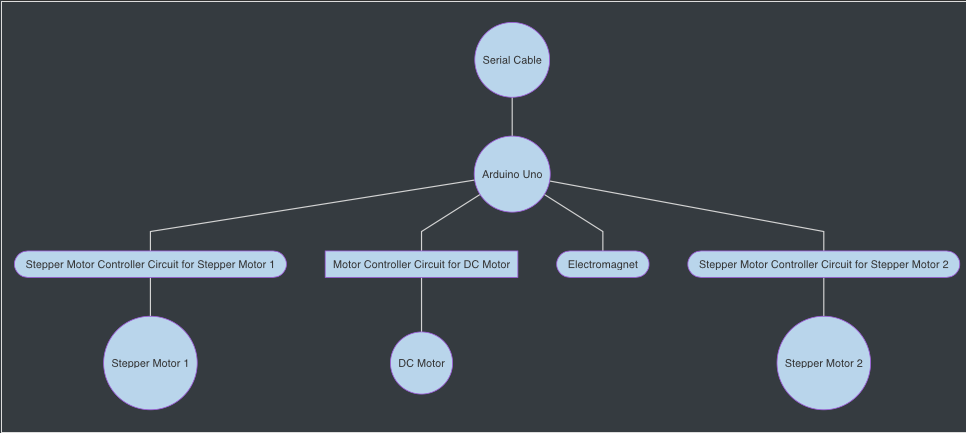

Design Diagram

System Overview

Note: everything that is on the block diagram is for the basic goals of the project. We will continue to update it as we build it.

Mechanical

We have two stepper motors, each attached to a rope that is tethered onto each top corner of the whiteboard. These are meant to be detachable so installing this device on a new whiteboard should not take a super long time. By rotating the stepper motors, we can change the lengths of the two strings that the device is hanging by. You can think of the ropes as bases, and the whiteboard surface to be the span.

We have a third rope that is attached to a regular DC motor on one end, and any of the bottom corners of the whiteboard. The DC motor will keep this rope constantly taught, pull the device closer to the board to provide pressure for writing.

We plan to use an electromagnet to retract and place the marker on the board. We’re not super sure about the mechanical aspects of this, but we are thinking of using the electromagnet to lift the pen off the board.

Cameras seem to be more challenging, so we will worry about vision later.

Electronics

The Arduino will receive a set of instructions via UART using the serial port. This is primarily to make it easier to switch to bluetooth later. These instructions will contain, one by one, the curves that the arduino is going to draw in “equation form”. We are not sure what is the best way to encode this information at the moment.

The Arduino will then transform the equations from xy form to extending and contracting the bases ropes. We may offload computing of this to an earlier stage in case it is too slow on the arduino. Once this calculation is complete, the actual bases stepper motors will be moved accordingly. We probably won’t want to use the stepper motor directly with the arduino, so instead we are considering building our own motor controllers if possible (otherwise we’ll buy them).

Once we are done drawing the curve, the pen will be lifted to avoid making marks unnecessarily by using the electromagnet. We will check the rx buffer to see if anything has been received. The device will then draw the next curve on the board.

Parts List

- Set of Serial Cable

- Arduino Uno

- 2 Stepper Motor Control Circuits and Motors

- Stepper Motor Driver

- Stepper motor

- 555 Timer IC

- Toggle Switch

- Printed Circuit Board

- DC Motor Controller Circuit and Motor

- 555 Timer Integrated

- PCB Terminal Blocks

- 2 5 * 5 PCB Board

- 2 1N4007 Diode

- IRFZ44 Power Mosfet

- 100uF Capacitor and 100nF Capacitor

- 100K Potentiometer

- 3mm LED

- 470R Resistor

- 10K Resistor

- Electromagnets

- Rope

Possible Challenges

- Device needs to have a significant grip on the surface, even for markers.

- For the basic device, capping the marker will be an issue. Either we have to provide a reminder for the user to recap the device (which is definitely an option) or we will need to have an auto capping feature before we can start using this seriously.

- The electromagnet should be carefully placed so it doesn't interfere with the other components. If it is too close to the motors or the microcontroller, damage may occur.

References

- DC Motor Controller Circuit- https://www.youtube.com/watch?v=WhwKheit6jw

- Stepper Motor Control Circuits and Motors - https://www.instructables.com/id/DIY-Stepper-Motor-Controller/