Group Members:

Lyuxing He (lyuxing2) - ECE 110

David Chen (sc60) - ECE 120

1. Introduction

Statement of Purpose

Nowadays many crucial tasks are conducted under the circumstance that expose human operators under hazard: underground mining, bomb-disarming, or nuclear power plan workers. Every time while they are at their workplace their lives are put under risks, but no robots or algorithms so far can replace their positions simply because of the demand of their own skills.Therefore, to best reduce the threat of their jobs to these skillful workers, we propose the "Remote Gesture-Control Robotics Arm" that enables workers to work in a safe remote place while still being capable of implementing their skills at work with precision.Background Research

Based on the research done over the course of 2017, electrical power-line installers and repairers are ranked the 10th most dangerous jobs among the country, with "26 fatal injuries and 1,710 nonfatal injuries". The most common reasons to injuries is "exposure to harmful substances or environments". Come from the same source, the statistics for mining machines operators cannot be underestimated either: "7 fatal injuries, 370 nonfatal injuries", and the main reason behind those injuries is "contact with objects and equipment". Over the course of researching similar projects, we did not find many related products being made and posted on the Internet, besides the Dexter Robot Arm created by Haddington Dynamics. Similar to the idea of our project, the Dexter Robot Arm work based on the own wills of the operators; however, the Dexter Robot Arm is controlled by moving the joints of another robot arm, and the input-arm and output-arm are connected by wires. In addition to that, the Dexter Robot Arm records the motion for playback. The Dexter achieves an impressive accuracy up to 50 microns with multiple well-designed encoders with the compromise of nearly $3000. On the other hand, our project aims to enable the workers to work in the same way but different places, and thus we will not try to accomplish the function of playback, but try to build a prototype that can perform imitation of operators' arm gestures with a precision that can be achieved under smallest budget.

2. Design Details

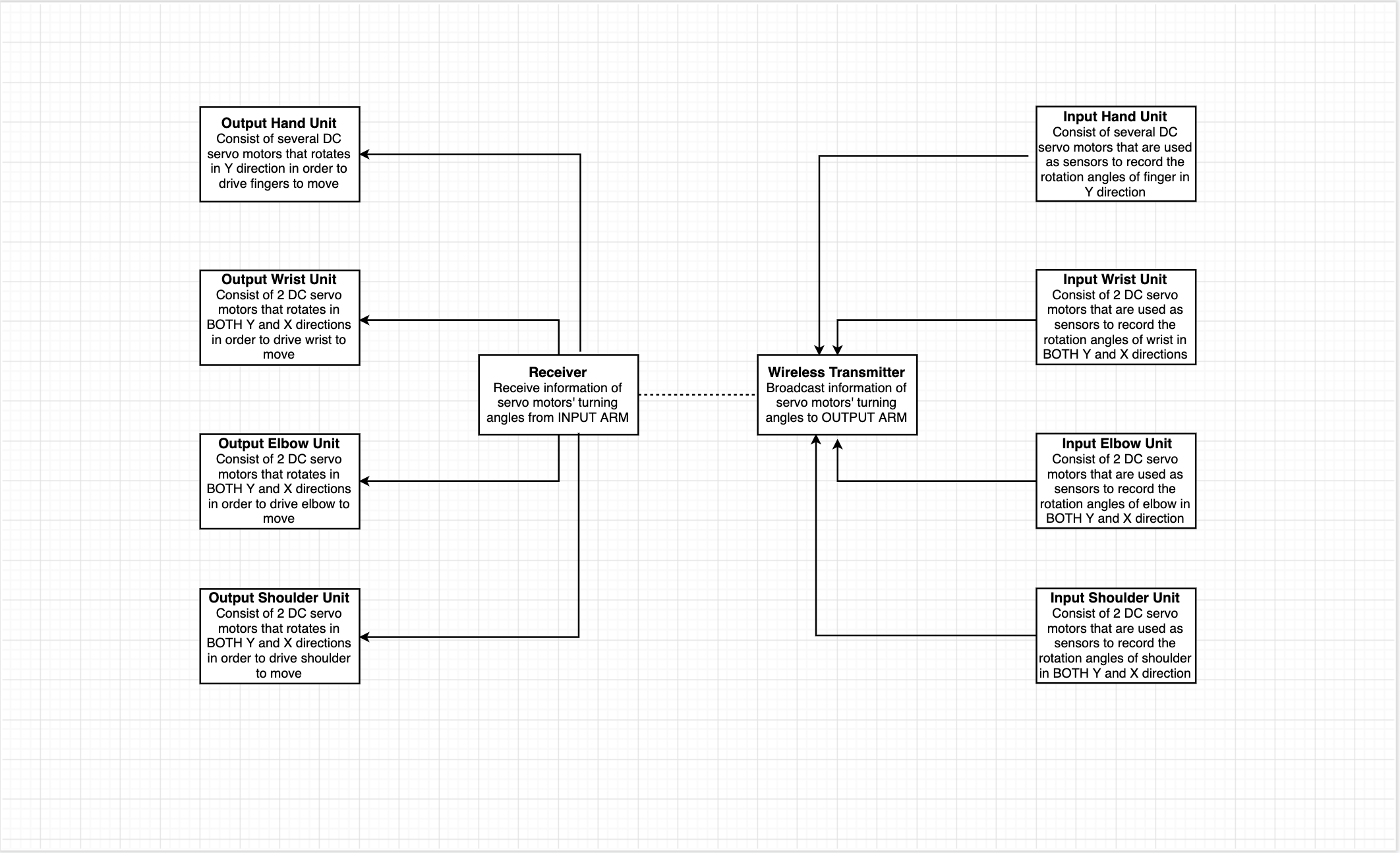

Block Diagram

3. Parts

Still looking for DC servo motors that can fit this project

Logic: We will use presumably Arduino developer board to implement logic as well as transmitting data between devices.

Sensor: We will mostly use angle sensors to measure the bending of the elbow and shoulder. We will also use flex sensor to measure the movement of the palm as well. All the sensor will be implemented as a whole kit so that the user can wear it easily.

4. Possible Challenges

The sensors in the shoulder unit require the highest precision, since a slight rotation around the shoulder and result in a noticeable change of position of the entire hands. In addition to that, using a servo motor as a sensor is just an ideology that flashes through our mind. No one in our group has ever tried this method before, and thus its precision and applicability remain unknown. what's more, there are some certain movements of arms are hard to be reproduced via a robotic arm. Lastly, it could also be difficult for us to drive the arm to rotate in a certain way with servo motor.

5. References

Statistics for High-Risk Jobs:

https://www.monster.com/career-advice/article/high-paying-dangerous-jobs

Hackday Newsletter for its 2018 Winner Dexter Robotic Arm:

https://hackaday.com/2018/11/03/dexter-robotic-arm-wins-the-2018-hackaday-prize/

Related video for Dexter Robotic Arm Project: