| Name | NetID | Section |

|---|---|---|

| Siddhant Kale | sskale3 | ECE 110 |

Karan Jain | karanj4 | ECE 110 |

| Jack Dayan | jydayan2 | ECE 110 |

Statement of Purpose

3D printers have been an essential tool in innovation and industry. Their ability to create almost any figure or form from design is bound to play a pivotal role in the coming decades. Thus, it is evident that this piece of technology will have a considerable footing in the time to come and won’t go anywhere. It is still evolving. Printing via multiple materials, on different scales, using different techniques. But there seems to be a necessary evolution not being looked at – portability. Personal 3D printers are amazing, cheap and efficient. However, currently the only way to move a 3D printer from one location to another is to dismantle it and assemble it at the target location. This is a rather time-consuming process, excluding the wear and tear that may take place in the transportation leading to loss of printing accuracy.

What if 3D printers could truly be portable? Portable like phones, laptops, or Play Station Portables. This will be the main goal of our project. Our goal is to create a 3D printer that one should be able to carry on their shoulders like a daily life object.

Background Research

To do this task, we have thought of making a foldable 3D printer that could fold and unfold like a laptop. We wish to design this folding frame mechanism from scratch. While designing this, these are some things we wish to achieve:

- It should be foldable without compromising sturdiness and accuracy of printing.

- It should be light, and slim – very similar to laptops.

- It should be easy to DIY assemble and repair.

- It should have minimalistic electronics on board

- It should be easy to access, control and connect. This would mean using phone applications or software to monitor, control and operate prints.

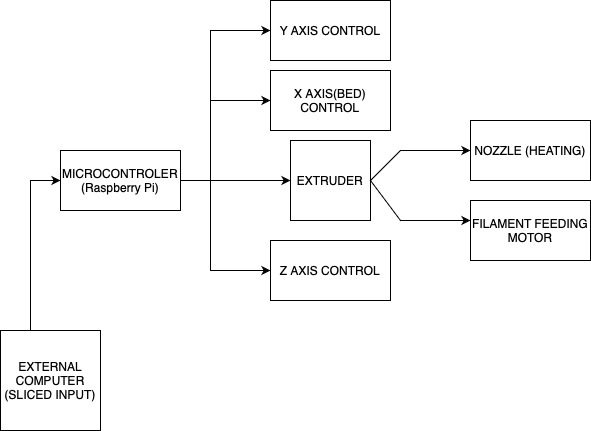

Block Diagram / Flow Chart

Provide a simple block diagram of your hardware design. A block diagram is a schematic graphic that shows the interactions between different components in a hardware or software system. If appropriate, please also include a flow chart showing the steps your design needs to go through to function. The online program draw.io is a great tool to create polished block diagrams and flow charts. Likewise Microsoft's visio is also a great program to create block diagrams and flow charts.

System Overview

Provide descriptions to your block diagram and flow chart. State the purpose of each block.

Parts

Electrical Components Required

Mechanical Component Required

Link:

Possible Challenges

This idea has some realistic and practical issues which are undeniable, and need to be looked at dealt with:

- Biggest issue being power source. Generating the high nozzle temperatures for long durations would naturally require power plugs and won’t operate on small DC power sources. However, if the assumption of ease of accessibility of power plugs is considered, this problem can be temporarily overlooked.

- Weight would be another issue to look at. Given the motors and the frame are heavy components, the net wet is something to research into to validate the rationality of this idea.

- Print volume might be reduced if the 3D printer is to fit on somebody’s back. It would require some major innovation in design to get the most printing volume from a practical dimension constraint set on the net size of the printer.

References

https://all3dp.com/2/how-to-build-a-3d-printer-from-a-kit-or-from-scratch/

https://www.hackster.io/DesiEngineer/how-to-make-a-big-3d-printer-at-home-using-arduino-4a7b79