| Name | NetID | Course |

|---|---|---|

| Jun Hao Wong | junhaow2 | ECE120 |

- Introduction

- Statement of Purpose

The objective is to create a mass-produceable product that can effectively address the issue of source separation of waste and be implemented in real life to replace conventional recycling bins. The idea behind the project is a bin which uses sensors and physical properties testing methods to autonomously identify and segregate waste according to the materials. Our goal will mainly focus on creating a effective and versatile identification (sensors) system that works in principle to one specific type of bin design.

The additional value of this project is in familiarizing ourselves with processes that can be scaled and applied to industrial production, such as characterizing objects using sensors and making electrical and mechanized parts to transport objects. - Background Research

The main motive behind creating an Automated Waste Segregation system is to address the inefficiency achieved by conventional recycling bins. Source separation has always been a major issue in the waste recycling industry and a hurdle in creating a circular economy. Creating and providing a commercially available AWS system is a way to make source separation a more reliable and accurate process, whilst reducing the amount of human labor required.

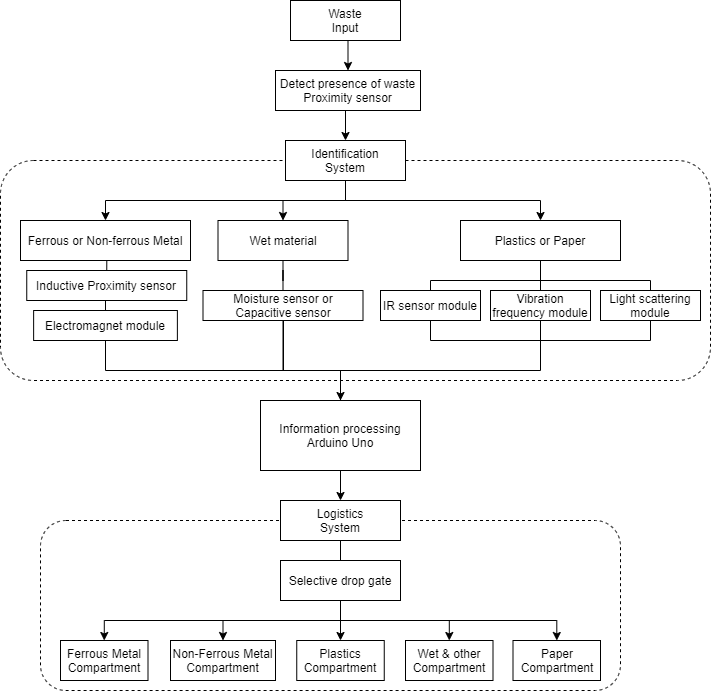

The bin can be broken down into two parts, the identification system and the logistics system. The design and making of identification system will be our primary concern, as it constitute the major part of the automation. The logistics system will start coming into consideration once the identification systems are in place. However, a functional proof of concept for logistics system will be developed such that the environment to calibrate and characterize the sensors to can be identified.

In terms of the identification system. Many versions of Automated Waste Segregation system prototype have been made and shared online, all of them uses multi-sensor design which we will implement [1][2][3]. Some of the type of sensors chosen are also adopted from these design (i.e. inductive proximity sensor). However, the issue with most of these design are that they are crude prototype that is not made for commercial use, they are capable of only categorizing few type of waste (i.e. metal, non-metals and wet material) and they have lower than 50% accuracy when identifying non-metallic waste [2]. Therefore, improvements have to be made to bring the design a step closer to being a commercially viable product. The project has high feasibility since the complexity of it can be adjusted (i.e. number of sensors, type of category we chose to identify, etc.) and it will be affordable because the sensors used are commercially available as parts for electronics project.

- Statement of Purpose

- Design Details

- Block Diagram

Diagram 1: block diagram of the overall system - System Overview

Diagram 2: Illustration of the concept for the logistics system

As illustrated in the diagram, the bin will have a closed lid that opens to the upper compartment surrounded by sensors. The openings of the bins will limit the size and shape of waste that can be thrown into it. Once the presence of waste is detected in the enclosed upper "sensing compartment" by ultrasound sensors, the other sensors will be switched on and do their respective testing in a sequenced manner.

While the testing is done, information will be fed into an Arduino Uno to check if the waste have been identified yet. Once a category have been identified, the system will switch to commanding the logistics system. This is when the t-frame will slide such that the opening to the respective bin opens directly under the drop gate. Finally, the drop gate opens and let the waste fall from where it initially sits.

The identification system will constitute few different type of sensors and physical testing modules as no one method can verify all types of materials we intend to identify. Sensors that requires close contact to the waste will be placed in the sensor compartment under the drop gate. Other sensors will be placed on the sides of the compartment. The t-frame which guides the opening of the bins can be made of sliding mechanism like those on 3D printer except it will run on two perpendicular axial that slides freely. The drop gate can simply be controlled by actuators and motors, depending on which can allow for simple but lasting design.

In terms of the test sequence, the first test initiated will be metals as they are the most straightforward to identify. Then to eliminate non-recyclable waste such as wet organic materials, this category will be identified and eliminated next. Plastics and paper differentiation will be the last tested as few sensors measurement is required. Waste that is still not identifiable will be disposed into the wet materials bin.

The project will be separated into 2 different stage. The first is to design and make the identification system works. Once sensors for metals, wet material and plastics/paper is tested and made to work as desired, more detailed focus will be given to working on the logistics system. However it is necessary to finalize the design of logistics system (initial design as shown in diagram 2) too, because sensor's placement, characterization and calibration will rely largely on its environment hence the overall design of the bin.

- Block Diagram

- Parts

- Inductive Proximity Sensor (x1) - 19

- Arduino Uno board (x1) - $25

- Capacitive proximity sensor (x1) - $20

- Ultrasound sensor (x2) - $10

- Breadboard (x2) - $10

- Electronics part to build circuit (wires, IC chip, resistors, etc.) - $10

- Infrared Photodiode (x1) - $3

- Motors/actuators(x5) - $30

- Electromagnet (x1) - $7

- Sound sensor module (x1) - $13

- Photoelectric sensor module (x1) - $10

- *InGaAs diode (x1) - $33

- Possible Challenges

Foreseeable issue include figuring out the type of sensors and physical properties testing methods to identify different materials. In particular, because there are no low-cost sensors that can directly identify one type of non-metallic waste from another. Indirect methods of testing have to be tested and determined to figure out which works best. To elaborate specifically, the test for wet materials, plastics and paper are not conclusive. In terms of wet materials, the capacitive sensor can be tuned to detect water as the dielectric constant of water is relatively large [4], but this is something that needs to be tested. In terms of plastics, the IR module will be our first choice for testing. However, since online information cannot confirm the data which a module like this will be able to collect from plastics, it again has to be made and tested. In addition to that, a common LED and Infrared photodiode might not produce EM wave (300nm-1000nm) that can be absorbed by plastics, then an InGaAs photodiode have to be used, as it detects EM wave of higher wavelength (900nm-1750nm) [5]. The process of figuring out these testing method and the physical design of the bin will likely be the main issue we have to work through to arrive at a successful product. - Reference

[1] A. Chandramohan, J. Mendonca, N. R. Shankar, N. U. Baheti, N. K. Krishnan and M. S. Suma, "Automated Waste Segregator," 2014 Texas Instruments India Educators' Conference (TIIEC), Bangalore, 2014, pp. 1-6.

[2] A. Sharanya, U. Harika, N. Sriya and S. Kochuvila, "Automatic waste segregator," 2017 International Conference on Advances in Computing, Communications and Informatics (ICACCI), Udupi, 2017, pp. 1313-1319.

[3] D. Perangin Angin, H. Siagian, E. D. Suryanto, R. Sashanti, and Marcopolo, “Design and Development of the Trash Spliter with Three Different Sensors,” Journal of Physics: Conference Series, vol. 1007, p. 12057, Apr. 2018, doi: 10.1088/1742-6596/1007/1/012057.

[4] Steck, Z. "The Basics: Capacitive Sensors and Dielectric Constants". Pepperl+Fuchs Blog. https://blog.pepperl-fuchs.us/blog/bid/306393/the-basics-capacitive-sensors-and-dielectric-constants (Accessed February 14, 2020).

[5] "Marktech Optoelectronics MTPD1346D-150, datasheet". Digi-Key Electronics. https://www.digikey.com/short/z3180n (accessed February 14, 2020).