Statement Of Purpose:

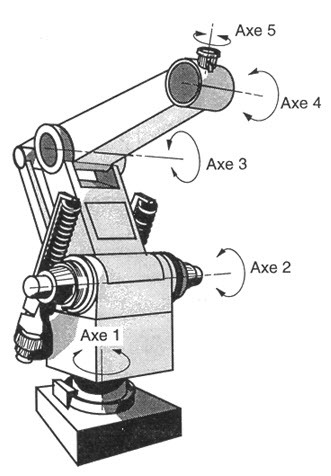

There are many situations where human like accuracy and versatility are required for a task, but the task is too dangerous and/or repetitive for an actual human to execute. These could be jobs in highly industrial areas, delicate object manipulation in a lab, or simply moving things from point A to point B with swift accurate motions. That is why we are planning on building a 5-axis robotic arm from affordable parts (Cheap servos and laser-cut balsa wood). We would like to be able to manipulate ob objects from a safe distance using this robotic arm.

System Overview:

Our 5-axis robotic arm will use an Arduino to control all of the servos directly. These servos will rotate all axis except the base "elbow" joint where the most weight will reside. That base joint will use a stepper motor controlled by a motor controller which will in turn be controlled by the main Arduino. To actually control the arm ourselves, we will use a wired remote, and the buttons on this remote will be directly wired to Arduino inputs. On the grabber portion of the arm, there will be a limit switch. When the arm successfully grabs onto something, the limit switch signal will go through a NOT gate which will turn an LED on the robotic arm OFF.

Background Research:

The first ever robotic arm was installed in 1962. It costed $25,000 and could lift upto a weight of 1815 kg. In 1969, Victor Scheinman invented an all-electric, 6-axis articulated robot designed to permit an arm solution. This allowed it accurately to follow arbitrary paths in space and widened the potential use of the robot to more sophisticated applications. We plan to much build a smaller 5-axis electric robotic arm with a much lower budget to help perform basic tasks with decent accuracy.

Project Expectations:

- Lift 300g of weight

- 0.4m long

Parts required:

- Arduino Uno

- Servo Motors

- Stepper Motors

- Logic Gates

- Batteries

- Buttons

- Wires

- Motor Controls

- Balsa Wood Plates / 3D - printed parts

- Nuts & Bolts

Possible Challenges:

- Inexperience with designing mechanical systems

- Inexperience with designing electrical systems

- Individual parts combined may exceed allowed budget if not careful

- Lack of knowledge concerning operating necessary fabrication equipment

References:

- http://iptmajorprojectjacobheffernan.weebly.com/history-of-the-robotic-arm.html

- https://www.intorobotics.com/best-projects-diy-robotic-arms/

Ronan Khamosh : khamosh2 : ECE 120

Calvin Field : calvinf2 : ECE 120