Topic 7: How do

dislocations move in a material?

Overview

The movement of dislocations produces plastic strain in a material,

and dislocations move in response to stresses; the Peach-Koehler

equation \(\mathbf{dF} = (\underline\sigma

\mathbf{b})\times \mathbf{dt}\) gives the force

dF per length dt on a dislocation

based on the stress \(\underline\sigma\). The plastic strain rate

\(\dot\gamma\) is derived from a

density of dislocations \(\rho_\perp\)

with Burgers vector \(b\) and velocity

\(v_\perp\) via the Orowan equation as

\(\dot\gamma = b\rho_\perp v_\perp\).

Thus, plastic strain response of a material to stress is “merely” a

matter of determining how dislocations move in a material. At the

simplest level, dislocations have a minimum stress (the “Peierls

stress”) required to initiate movement. Beyond that, it can be difficult

to quantitatively measure the relationship between stress (or force) and

dislocation velocity in a material.

For materials with very low Peierls stresses (such as most

face-centered cubic metals), the dislocation mobility is primarily

dominated by phonon drag. However, for body-centered cubic metals or

other materials with high Peierls stresses, other defects are required

for dislocations to move: pairs of kinks are nucleated, and move along

the dislocation. Other processes, like cross-slip of screw dislocations,

also require the formation and movement of kinks. Furthermore, climb

motion of edge dislocations involve the elimination of vacancies at

jogs. Thus, for many situations, dislocation motion requires other

“defects.”

Reading

For this topic, you’ll want to review a few computational results on

dislocation mobility and kinks in body-centered cubic materials, along

with a paper on solid solution effects to have a sense of what is now

feasible for computational studies of kinks.

- S. Queyreau, J. Marian, M. R. Gilbert, and B. D. Wirth, “Edge

dislocation mobilities in bcc Fe obtained by molecular dynamics.”

Phys. Rev. B 84, 064106 (2011): doi:10.1103/PhysRevB.84.064106

- T. D. Swinburne, S. L. Dudarev, S. P. Fitzgerald, M. R. Gilbert, and

A. P. Sutton, “Theory and simulation of the diffusion of kinks on

dislocations in bcc metals.” Phys. Rev. B 87,

064108 (2013): doi:10.1103/PhysRevB.87.064108

- Y.-J. Hua, M. R. Fellinger, B. G. Butler, Y. Wang, K. A. Darling, L.

J. Kecskes, D. R. Trinkle, Z.-K. Liu, “Solute-induced solid-solution

softening and hardening in bcc tungsten.” Acta Mater.

141, 304-316 (2017): doi:10.1016/j.actamat.2017.09.019

Team assignment

Thermally-activated slip (the primary deformation mode for \(T\lesssim 0.15 T_\text{melt}\)) in BCC

metals occurs via the nucleation of kink pairs, followed by the motion

of the kinks along \(\frac{a}{2}\langle111\rangle\) screw

dislocations. This physical model has been the basis for discrete

dislocation dynamics computation of BCC metals through dislocation

mobility, as well as our understanding of solute interactions with

dislocations in BCC metals, such as solid-solution softening. An

interesting new class of BCC alloy are multi-principal element

alloys; TiZrNbHfTa is one such example. Your team has decided to

try to build a numerical model of yield strength as a function of

temperature and strain rate for this material.

- What computational method(s) would you plan to use for this problem,

and what might you find?

- What experiment(s) would you suggest to provide either validation or

additional information?

Prelecture questions

- Jogs are formed when one dislocation cuts through another. Can kinks

be formed this way as well? Either provide an example of how this could

happen, or explain why it cannot.

- Explain the role of jogs in dislocation climb. Can you write down an

expression for dislocation climb velocity in terms of jog density,

excess (above equilibrium) vacancy density, and any other quantities you

believe to be relevant?

- Derive an estimate of kink energy and width using the

Peierls-Nabarro model combined with line energy. The most

straightforward way is to consider a dislocation line that is straight,

except for a kink segment; treat this kink as a straight line

where the straight segments sit in

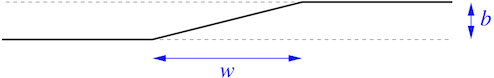

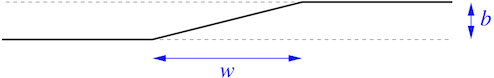

Peierls “valleys” of zero energy separated by a distance \(b\), and the kink of width \(w\) crosses between the two valleys. If the

dislocation position in the valley is given by \(u(x)\), then the Peierls energy (slip

energy as the dislocation moves from one valley to another) is \[\int_{-\infty}^{\infty}

\frac{W_\text{P}}{2}\left\{1-\cos\left(\frac{2\pi

u(x)}{b}\right)\right\}dx.\] for a Peierls barrier \(W_{\text{P}} = b^2 \tau_{\text{P}}/\pi\)

and Peierls stress \(\tau_{\text{P}}\).

The other contribution to the energy is the line energy, which is given

as an energy per length of \(W_0 \approx

\frac12 Gb^2\).

where the straight segments sit in

Peierls “valleys” of zero energy separated by a distance \(b\), and the kink of width \(w\) crosses between the two valleys. If the

dislocation position in the valley is given by \(u(x)\), then the Peierls energy (slip

energy as the dislocation moves from one valley to another) is \[\int_{-\infty}^{\infty}

\frac{W_\text{P}}{2}\left\{1-\cos\left(\frac{2\pi

u(x)}{b}\right)\right\}dx.\] for a Peierls barrier \(W_{\text{P}} = b^2 \tau_{\text{P}}/\pi\)

and Peierls stress \(\tau_{\text{P}}\).

The other contribution to the energy is the line energy, which is given

as an energy per length of \(W_0 \approx

\frac12 Gb^2\).

Suggested background

These may help you think about the papers and questions raised; you

may want to look beyond these, too.

Discussion: Nov. 12-14, 2024

where the straight segments sit in

Peierls “valleys” of zero energy separated by a distance \(b\), and the kink of width \(w\) crosses between the two valleys. If the

dislocation position in the valley is given by \(u(x)\), then the Peierls energy (slip

energy as the dislocation moves from one valley to another) is \[\int_{-\infty}^{\infty}

\frac{W_\text{P}}{2}\left\{1-\cos\left(\frac{2\pi

u(x)}{b}\right)\right\}dx.\] for a Peierls barrier \(W_{\text{P}} = b^2 \tau_{\text{P}}/\pi\)

and Peierls stress \(\tau_{\text{P}}\).

The other contribution to the energy is the line energy, which is given

as an energy per length of \(W_0 \approx

\frac12 Gb^2\).

where the straight segments sit in

Peierls “valleys” of zero energy separated by a distance \(b\), and the kink of width \(w\) crosses between the two valleys. If the

dislocation position in the valley is given by \(u(x)\), then the Peierls energy (slip

energy as the dislocation moves from one valley to another) is \[\int_{-\infty}^{\infty}

\frac{W_\text{P}}{2}\left\{1-\cos\left(\frac{2\pi

u(x)}{b}\right)\right\}dx.\] for a Peierls barrier \(W_{\text{P}} = b^2 \tau_{\text{P}}/\pi\)

and Peierls stress \(\tau_{\text{P}}\).

The other contribution to the energy is the line energy, which is given

as an energy per length of \(W_0 \approx

\frac12 Gb^2\).